EDC Building | Fault Detection & Diagnostics | Coil Valves

Coil Valves

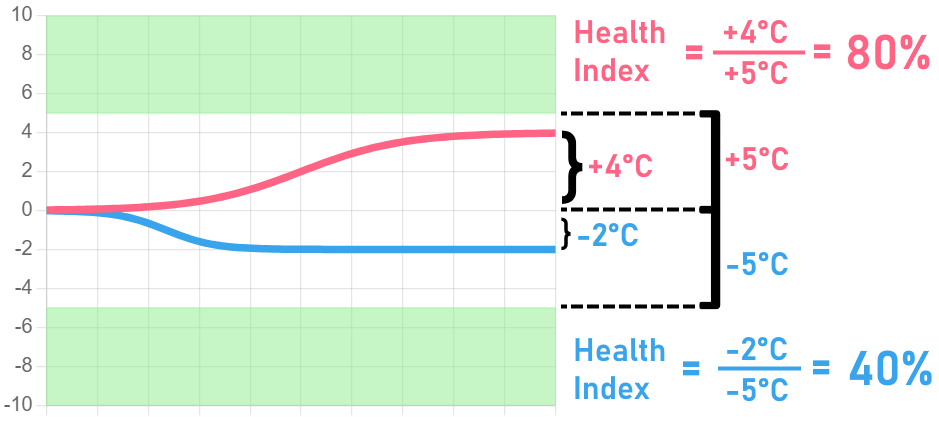

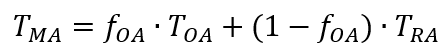

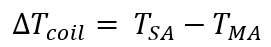

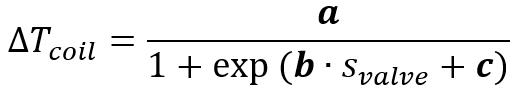

The Delta Air Temperature chart lets you monitor the change in air temperature across the heating and cooling coil. The AHU's heating/cooling coils increase or decrease the temperature of the mixed air to the desired supply/discharge air temperature. A rise in temperature is expected to occur when the heating coils are active (i.e., heating coil valves are open) and decrease when the cooling coils are active. If these changes in air temperature are not observed, a seized or uncalibrated heating/cooling coil valve may be the cause. Faulty coils or valves may result in unexpected supply air temperatures, causing occupant discomfort or excess energy use at the zone/VAV-level as zones struggle to maintain temperature setpoints.

Faulty cooling coil valve! ❌

Observed: The greatest air temperature change across the cooling coil falls short of -5℃.

Just right! ✅

Observed: The greatest air temperature change across both the respective coils meets or exceeds ±5℃.

Faulty heating coil valve! ❌

Observed: The greatest air temperature change across the heating coil falls short of +5℃.

Low Health Index!

Turbo

Low Health Index!

Turbo